CHEMICAL

Dry milling and classification for plastics and polymers.

Synthetic polymers are man-made polymers. They are obtained by polymerization of monomers, which are themselves generally derived from the petroleum industry. The plastic material is the result of a formulation based on polymer and additives (plasticizer, colorant, filler,).

The POITTEMILL Group offers a wide range of techniques for all stages of plastics and polymer processing, from pre-grinding to ultra-fine grinding and high-performance classification, meeting the standards of today’s and tomorrow’s manufacturers.

Plastics & polymers

Sustainable processing solutions

Fully integrated solutions are the key to providing optimised processes that help you both reduce costs and make more sustainable use of valuable resources.

These systems are based on the principle of:

• Reliability and safety

• Low operating and maintenance costs

• Guaranteed hygienic, customer-oriented process solutions

• Easy cleaning

• Energy saving

The diverse characteristics of powders in these types of industries require a combination of engineering skills and experience to design quality systems to meet the expectations of today’s and tomorrow’s customers.

Plastics & polymers

Nos solutions

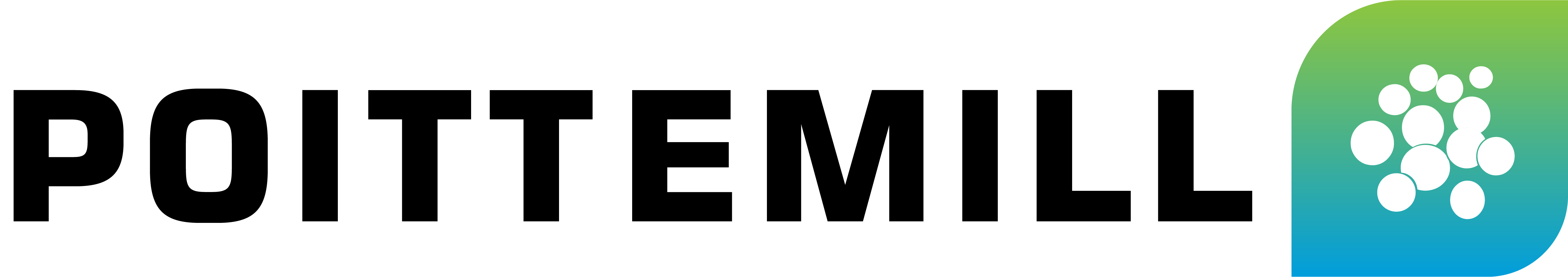

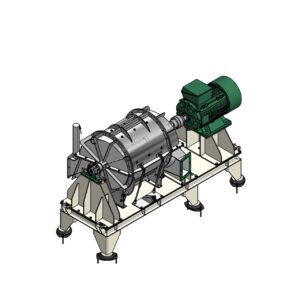

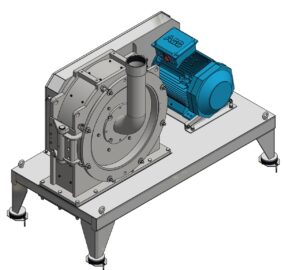

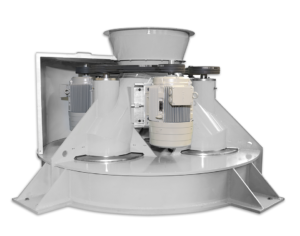

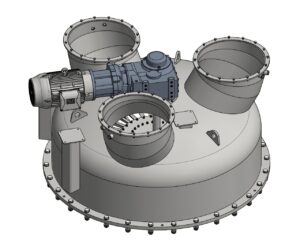

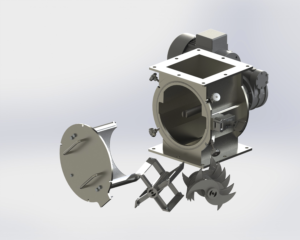

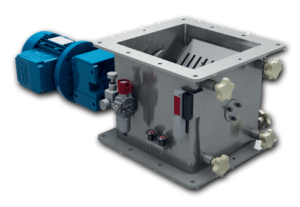

The ATTRIMILL attrition mill is very useful for reducing the particle size of fibrous materials, plastics or other materials that are not easily shredded by conventional grinding technologies. This equipment accepts heat sensitive and soft materials more easily without cooling gas injection. This is achieved through a combination of three physical principles that generate highly efficient ultra-fine grinding: self-shredding of particles in the upward vortices generated by a strong air stream, impact against the blades and stator, and shearing of particles between the blade tips and stator flutes. With specific settings for each product, and if necessary with the addition of a separator, the fineness of the ground product can reach a few tens of microns, and the grinding rate can reach up to 25 tons per hour with a single piece of equipment.

POITTEMILL has also developed other processes with its attrition mill, notably in the sorting and recovery and revalorisation of precious materials in electronic waste, motherboards and graphic cards of obsolete computers. This unique and patented process consists of simultaneously crushing and separating metals from polymers. This innovative solution, which is in line with the current trend to recycle all materials, makes it possible to treat a large part of the urban mines of electrical and electronic waste.

Plastics & polymers

Process testing and development

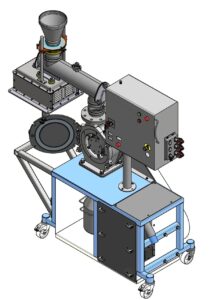

The POITTEMILL Group has its own scientific laboratory as well as a test center which is unique in France. It is in this test center that the dialogue between customers and the technical teams begins, but it is also here that detailed analyses of their raw materials are carried out to obtain complete information on the execution of the task set.

Our development and engineering team is always available to help you explore new and innovative processes and applications.

Our testing facilities offer exceptional opportunities to test ingredients, machines, parameters, and processes, whether in the laboratory, pilot or industrial scale, to ensure you achieve the necessary product quality and operating efficiency.

Plastics & polymers

Type of tests

Classification - grinding

Test including drying

Test including inerting

Cryogenic test

Test including FORPLEX grinding equipment

Crushing and Screening Test

Plastics & polymers

Particle size analysis

Hardgrove grindability index (HGI)

Laser particle size measurement - dry grinding / Lab Sieve

Moisture measurement

NIR analysis

CONTACT US

Do you have a project in mind? Need information?

At the forefront of innovation, the POITTEMILL Group has been designing its own equipment for over 90 years, offering customized turnkey solutions.

Plastics & polymers

Equipement

Plastics & polymers

Sustainable processing systems

In the context of the climate emergency, the environment is the strategic priority of the POITTEMILL Group. The Group approaches it with the ambition to offer processing technologies that maximise production efficiency while minimising your carbon footprint. In addition, our POITTEMILL Group dry powder processing technologies are developed to support and integrate a more sustainable life cycle.