Drying and grinding installation

grinding and drying process for food and feed, pharmaceutical, ingredients, minerals powders.

GRINDING AND DRYING

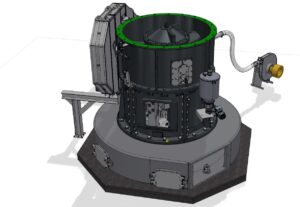

POITTEMILL PROCESS OF SIMULTANEOUS GRINDING AND DRYING WITH PENDULUM MILL.

Process

The natural moisture in quarries or moisture resulting from industrial processing often requires the grinding of wet products. Air separation allows the grinding or pulverization of raw materials containing a small percentage of water without prior drying. However, beyond a certain water content (variable depending on the products), drying becomes necessary. A hot generator is then required to supply and introduce, at a point in the circuit, placed under depression, the essentiel hot air for drying.

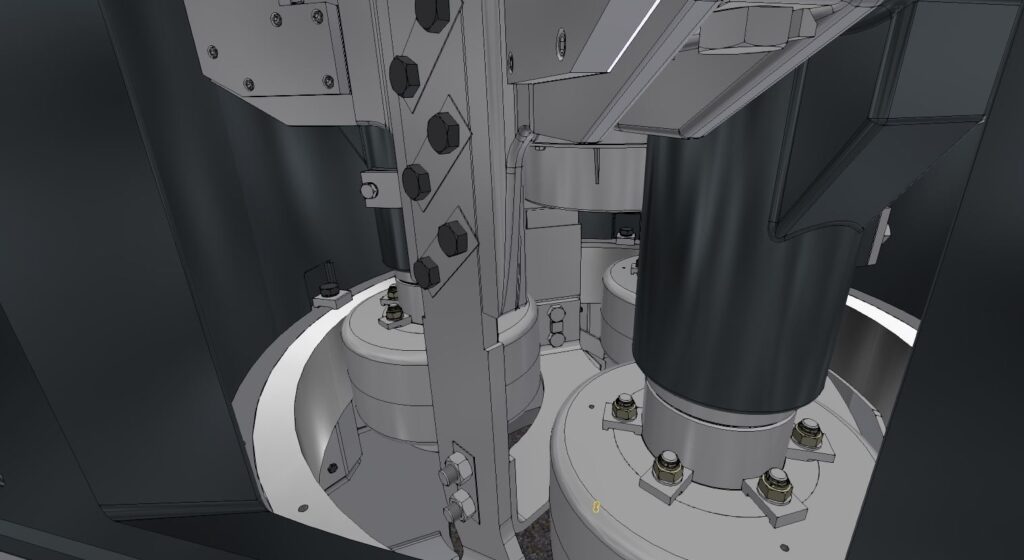

Thanks to its ventilation system, the pendulum mill POITTEMILL with air separation allows simultaneous drying and grinding under optimal conditions. Indeed, drying under these conditions is accelerated by the ventilation in the mill and separator, as well as by the grinding itself, which, by reducing the grain size, facilitates reaching the internal moisture more effectively.

In the case of grinding with simultaneous grinding, it will also be necessary to plan the evacuation of water vapors and excess air.

MANUFACTURING MATERIALS ADAPTED TO YOUR REQUIREMENTS

- STAINLESS STEEL for foodstuff, chemical or pharmaceutical uses.

- ANTI-ABRASIVE LININGS for abrasive products

Functioning

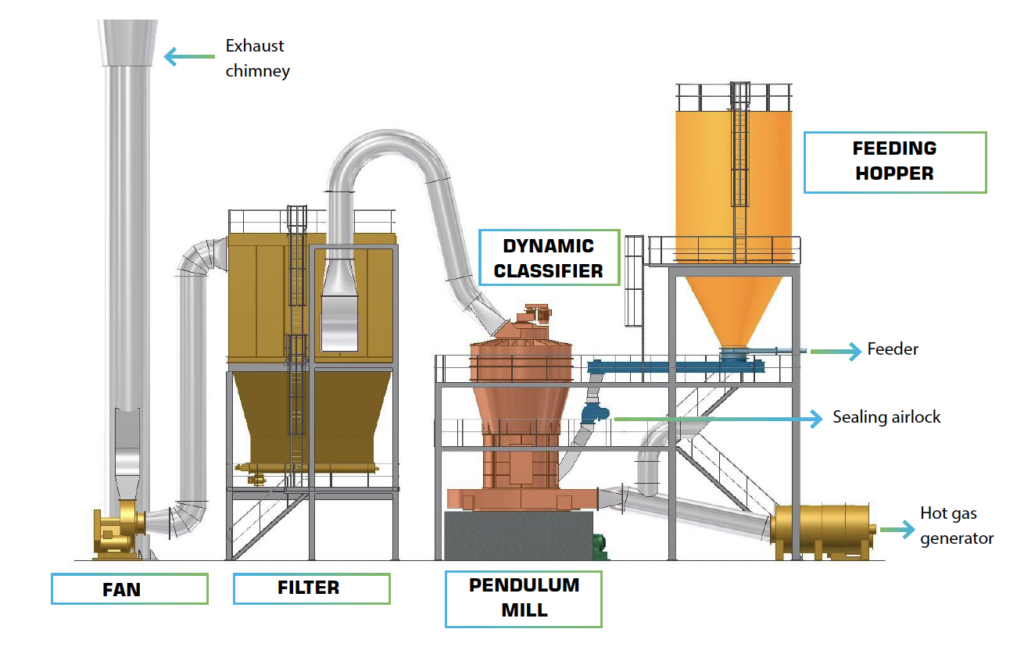

The raw and wet product is extracted from the feeding hopper by a specific extractor and introduced into the pendulum mill through an airlock ensuring a tight seal.

A hot air generator provides the necessary heat to warm the air passing through the mill and enable the drying of products during grinding.

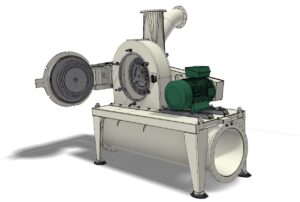

The ground particles are classified by a dynamic separator, allowing only particles that have reached the desired fineness to pass through.

The hot and moisture-laden air passes through a self-cleaning filter to separate the air from the dust.

The clean, moisture)-laden air is discharged through the exhaust chimney, while the fine particles are continuously extracted from the filter.

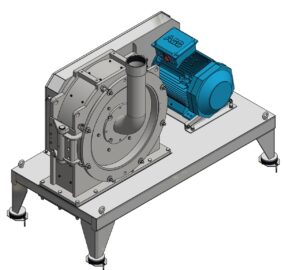

The entire process operates under vacuum thanks to a fan placed at the end of the chain, which ensures the creation of the air flow and the necessary pressure drops for the proper functioning of the equipment.

Residual hot air can be partially recirculated to the mill’s air inlet to recover the remaining available heat (up to 30%), thereby reducing energy consumption.

Advantages

The operation of simultaneous grinding and drying allows a significant reduction in the investment cost of the unit and significantly lightens the energy bill by at least 30% compared to a conventional system (drying and grinding in two separate stages).

POITTEMILL also explores heat recovery solutions that are often available in factories (kilns, calciners, superheated steam, etc.) and adapts its processes accordingly to optimize energy expenditure.

Simultaneous grinding and drying.

Energy produced by grinding recovered for drying operation.

Grinding temperature control with ambient or cooled air for temperature sensitive products.

Particle size control in association with a classifier or a sifter.

Safety of grinding.

Inert gas is injected for flammable products.

CONTACT US