FOOD & FEED | PROTEIN ALTERNATIVES

Protein enrichment by dry process

A very important step in the value chain of the food industry, a good preparation of the powder will always give a better end product.

In order to meet the needs and requirements of producers of special flours and ingredients, POITTEMILL has developed a range of patented industrial processes dedicated to the food industry with solutions designed to produce a wide range of possible end products or by-products, obtained only by fine grinding, particle size reduction, separation and classification of applications.

Our expertise

PROCESS

- DEHULLING PROCESS

- CONCENTRATE PRODUCTION (ENRICHMENT)

- CO-PRODUCT VALORISATION

- SPECIAL FLOUR (FINE MILLING)

A wide range of possible appliations

Oilseeds: rapeseed, sunflower, walnuts, almonds, lupins

Pulses: peas, yellow peas, chickpeas, beans, mungbeans, lentils

Cereals: wheat, maize, barley, oats, rice, starch, semolina

But also: seaweed, insects, potatoes, asuki, hemp, quinoa

Sustainable processing solutions

These systems are based on the principle of:

• Reduction of the number of equipment and process steps.

• High quality product, high purity of the powder.

• Reliability and safety.

• Reduced operating and maintenance costs.

• Guaranteed hygienic, customer-oriented process solutions.

• Easy to clean.

• Energy saving.

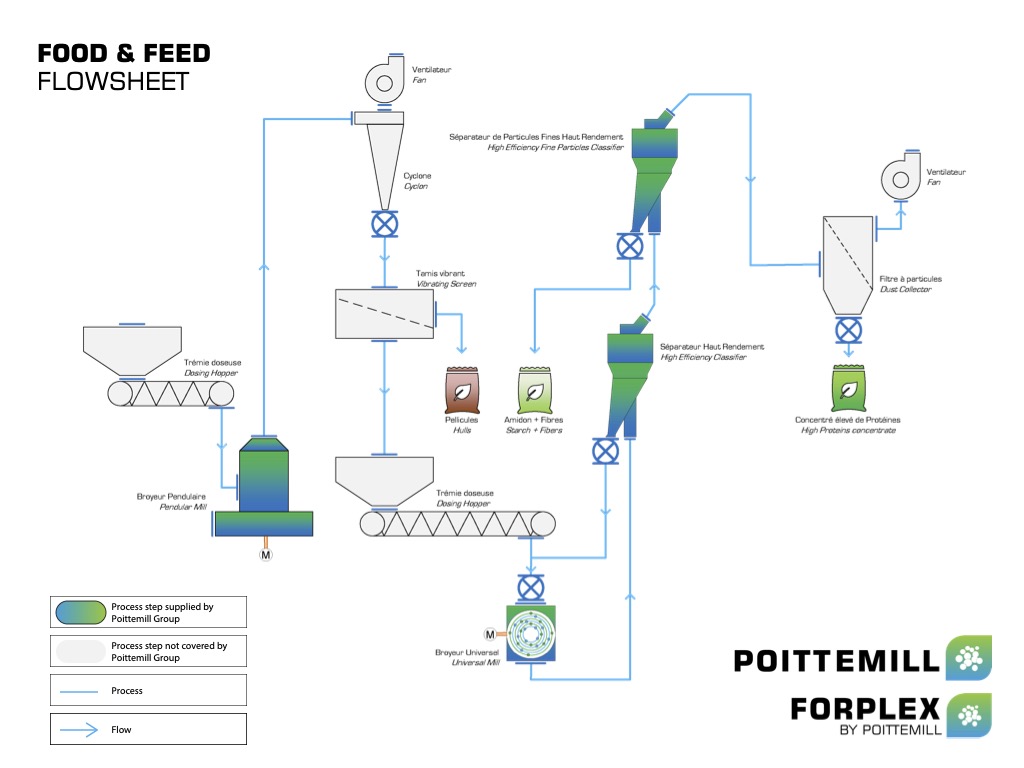

Process for protein extraction

Case study: protein enrichment

After a dehulling stage of the raw products to remove all shells, the seeds go through a dry fractionation process to obtain a flour.

It is in this flour that POITTEMILL is able to obtain a protein-rich fraction superior to the initial product, only by disassembling and separating the particles. This process is possible for all products that can be transformed into flour: vegetables, cereals, oilseeds, etc.

After an impact, attrition or compression grinding stage, depending on the uses and needs of the project, the ground product is passed through a high efficiency SHRv separator. It is in this decisive stage that the protein-rich fraction is isolated. By breaking down and separating the starch granules, fibre cells and proteins, the protein-rich isolate can now be used to enrich an existing powder to achieve very high protein levels in the initial product.

With grinding maintaining a high level of product purity and efficient separation at a precise cut level, protein yields are higher than with other forms or designs of classifier. Once the right parameters and settings are found for the product, protein values more than 70% can be achieved in a fraction of 25-30% of the initial product.

Protein enrichment process

Our solutions

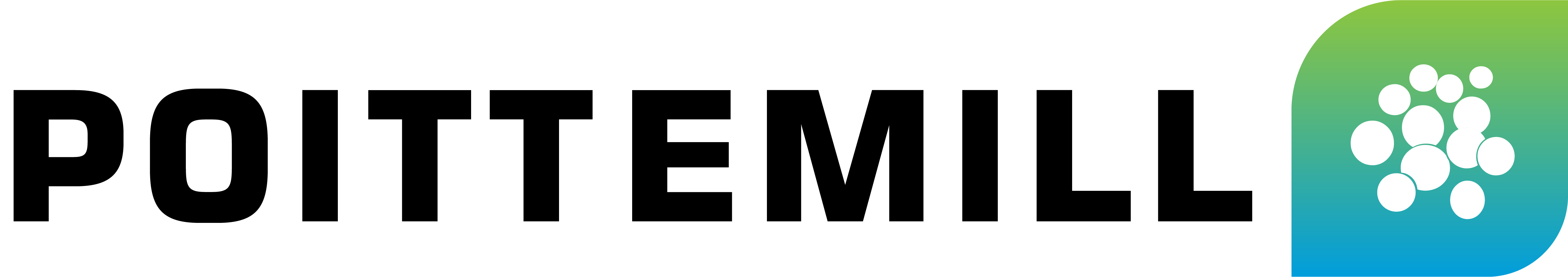

The ATTRIMILL is an attrition mill (or kinetic mill) combining several physical principles to generate efficient ultra-fine grinding: self-shredding of particles in upward vortices generated by a strong air stream, impact against the blades and stator, and shearing of particles between the blade tips and stator splines.

The ATTRIMILL works by propelling the material through an air circuit, the material is progressively pulverised along the rotor by impact against the blades and stator grooves and by self-communition when the particles impact with each other.

• Simultaneous grinding-drying process

• Grinding temperature control

• Fibre retention

• Particle size control

Our solutions

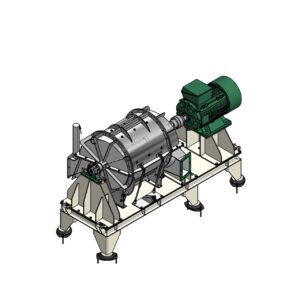

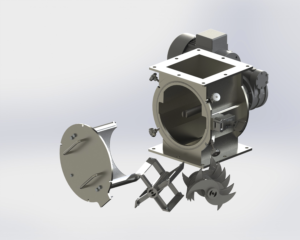

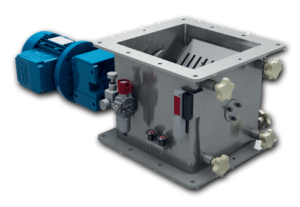

This impact crusher has two rotors driven in opposite directions, which allows much higher linear speeds than the FNG universal crusher with only one rotor (up to 200 m/s).

The product is fed into the centre of the shredder. The grinding is carried out by impact and attrition of the raw material between 2 grinding plates. The fineness of the material can be adjusted by the speed of the rotation or the feed rate but also by adjusting the air gap between the rotors.

RCW is preferred for fibre-free feeding applications with moderate production capacity to reduce the CapEX of the installation.

• High fineness rate

• Accepts special products

• Reduced ground clearance

• Very easy to clean

Our solutions

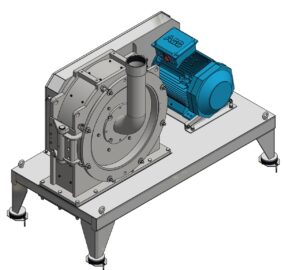

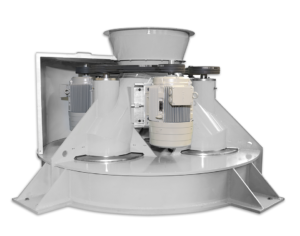

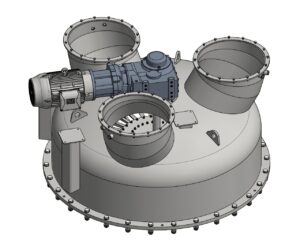

The SHR is the latest generation of our high efficiency dynamic classifier. Our new SHR is used to separate a wide range of particles (d98 – 5 – 1000µm) at a high level of efficiency.

The SHR is equipped with our patented SEALMAX® seal, which allows a clean cut, even at very high fineness. It has been designed to be coupled with all types of shredders in the POITTEMILL range. To improve the efficiency of this type of separator, POITTEMILL has designed an original air purge system that extends the product’s residence time in the selection zone. With this solution, the recycling becomes external, and the rejection of the installation is now measurable and visible.

Thanks to its high efficiency and maximum output, this classifier is very useful for post separation processing, such as enrichment or protein concentration. The classification module consists of one or two classifiers placed at different locations in the process loop to separate the protein-rich milled product fraction and by-products, which can be used in different applications.

• Easy control of rejects

• Easy control of the particle size of the final product

• High level of fineness and cutting accuracy

Sustainable processing solutions

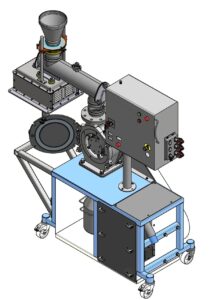

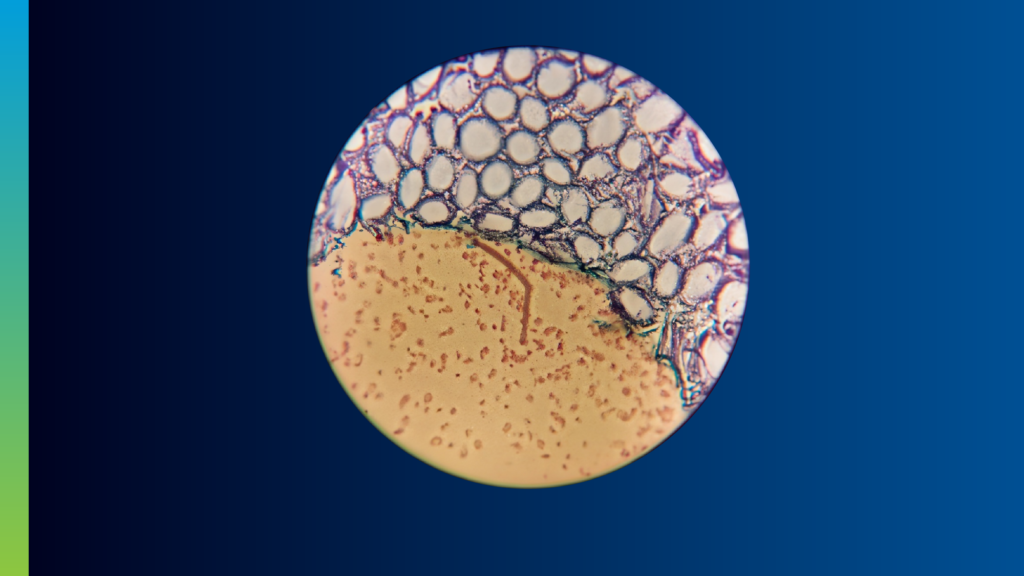

Process testing and development

The POITTEMILL Group has its own scientific laboratory as well as a test center which is unique in France. It is in this test center that the dialogue between customers and the technical teams begins, but it is also here that detailed analyses of their raw materials are carried out in order to obtain complete information on the execution of the task set.

Our development and engineering team is always available to help you explore new and innovative processes and applications.

Our testing facilities offer exceptional opportunities to test ingredients, machines, parameters, and processes, whether in the laboratory, pilot or industrial scale, to ensure you achieve the necessary product quality and operating efficiency.

Type of tests

Classification - grinding

Test including drying

Test including inerting

Cryogenic test

Test including FORPLEX grinding equipment

Crushing and Screening Test

Particle size analysis

Hardgrove grindability index (HGI)

Laser particle size measurement - dry grinding / Lab Sieve

Moisture measurement

NIR analysis

CONTACT US

Do you have a project in mind? Need information?

At the forefront of innovation, the POITTEMILL Group has been designing its own equipment for over 90 years, offering customized turnkey solutions.

Alternative proteins

Equipement

Sustainable processing systems

In the context of the climate emergency, the environment is the strategic priority of the POITTEMILL Group. The Group approaches it with the ambition to offer processing technologies that maximise production efficiency while minimising your carbon footprint. In addition, our POITTEMILL Group dry powder processing technologies are developed to support and integrate a more sustainable life cycle.