Process for protein extraction

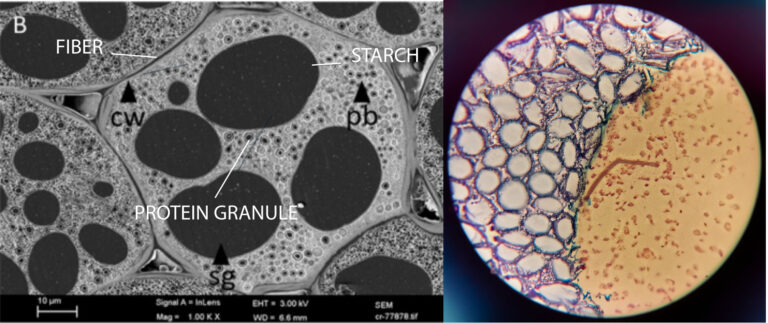

Protein extraction is an important process in the food industry, particularly for the production of plant-based protein products. Grinding and classification are commonly used methods for protein extraction from plant materials, as they can help to break down the cell walls and release the protein from the plant cells.

Here’s a brief overview of the protein extraction process using grinding and classification:

- Grinding: The raw plant material is typically ground using specialized equipment such as hammer mills, roller mills, or impact mills. The grinding process breaks down the plant material into smaller particles, which can help to release the protein from the cell walls.

- Classification: After grinding, the particles are typically separated into different size fractions using a process called classification. This can be achieved using a range of methods, such as sieving, air classification, or cyclone separators. The purpose of classification is to ensure that the particles are of a consistent size and to remove any unwanted impurities.

- Protein extraction: The ground and classified material is then typically subjected to a protein extraction process, which can involve a range of techniques such as solvent extraction, enzymatic hydrolysis, or acid precipitation. The specific method used will depend on the type of protein being extracted and the desired properties of the final product.

- Purification: After extraction, the protein is typically purified to remove any remaining impurities and to concentrate the protein into a more usable form. This can be achieved using techniques such as filtration, centrifugation, or chromatography.

Overall, the grinding and classification process plays an important role in protein extraction from plant materials, as it helps to break down the cell walls and release the protein from the plant cells. By using specialized equipment and techniques, it is possible to extract high-quality protein from a range of plant sources, which can be used to produce a variety of food and feed products.

Case study: Protein enrichment

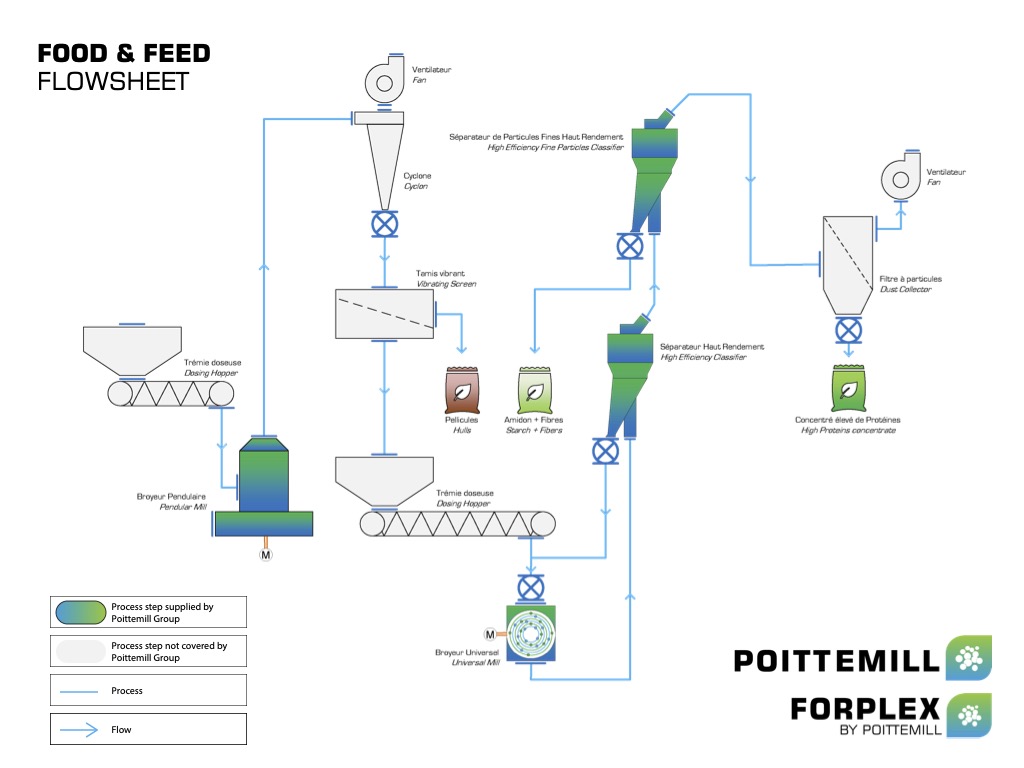

After a dehulling stage of the raw products to remove all shells, the seeds go through a dry fractionation process to obtain a flour.

It is in this flour that POITTEMILL is able to obtain a protein-rich fraction superior to the initial product, only by disassembling and separating the particles. This process is possible for all products that can be transformed into flour: vegetables, cereals, oilseeds, etc.

After an impact, attrition or compression grinding stage, depending on the uses and needs of the project, the ground product is passed through a high efficiency SHRv separator. It is in this decisive stage that the protein-rich fraction is concentrated. By breaking down and separating the starch granules, fibre cells and proteins, the protein-rich concentrate can now be used to enrich an existing powder to achieve very high protein levels in the initial product.

With grinding maintaining a high level of product purity and efficient separation at a precise cut level, protein yields are higher than with other forms or designs of classifier. Once the right parameters and settings are found for the product, protein values more than 70% can be achieved in a fraction of 25-30% of the initial product.

POITTEMILL’s process equipment offers several solutions:

- Dry particle size reduction

- Fine and ultra-fine grinding

- Dehulling

- Classification

- Protein extraction (concentrate)

- Co-products valorization

An expertise in various raw matierals

Our decades of process know-how and equipment design enable us to create efficient and responsible methods for hulling and extracting proteins from a wide range of raw materials such as:

- Soybean

- Pea

- Lupine

- Rice

- Corn

- Faba bean

- Mung bean

- Chickpea

- Lentils

- Oat

- Wheat

- Hemp

- …

Need help configuring your process?

Take advice from the POITTEMILL Group, experts in food processing, drying and classification technology, to ensure you take full advantage of the huge growth in the insect protein market. Our laboratory and test centre in France offers

numerous opportunities to test machines, parameters and processes, at pilot and full scale, to ensure that your product quality and operational efficiency generate the maximum return on investment for your business.