Grinding calcium carbonate: techniques, challenges and applications

Heavy calcium carbonate, or ground calcium carbonate, is a mineral material widely used for its exceptional properties. Made from natural carbonate minerals, it is characterised by high chemical purity, good inertness, thermal stability up to 400°C, whiteness and low oil absorption. Its low hardness, low abrasion value and excellent dispersion make it a popular functional inorganic filler in many sectors, including paper manufacture, plastics, paints and rubber.

Properties and applications of calcium carbonate

Calcium carbonate is valued for its physical and chemical properties, which make it suitable for a variety of industrial applications:

- Paper manufacture (60% of global consumption): Used for its whitening qualities and its ability to improve the texture and opacity of paper.

- Plastics: Improves the rigidity and reduces the cost of plastic materials, while maintaining good mechanical properties.

- Paints and coatings: Used to adjust the gloss, viscosity and durability of paints.

- Rubber and construction: Improves the mechanical strength and stability of end products.

The characteristics of calcium carbonate, such as mesh count, whiteness and calcium carbonate content, determine its suitability for specific applications. For example:

- 325 mesh, 95% whiteness, 98% content: Ideal for papermaking.

- 400 mesh, whiteness 95%, content 99%: Suitable for plastics.

- 2500 to 6500 mesh: Used in the manufacture of top-of-the-range paper, meeting the requirements of extreme fineness and high performance.

The challenges of grinding calcium carbonate

- High abrasion: Calcium carbonate is an abrasive mineral, which causes rapid wear to grinding equipment. This requires careful selection of the materials of construction of the machines to prolong their life.

- Granulometry control: Achieving a uniform granulometry adapted to the specific needs of applications can be complex. Precise control of grinding parameters, such as rotation speed and grinding time, is essential.

- Dust Management: Dry grinding can generate a significant amount of dust, requiring filtration and extraction systems to protect the working environment and the quality of the final product.

Dry grinding using a pendulum mill: an optimised solution

→Dry grinding with a pendulum mill (or vertical mill) is an effective method for producing calcium carbonate powders of different finenesses, suitable for a variety of industrial needs.

Calcium carbonate grinding

Calcium carbonate (CaCo₃) is an essential mineral used in a variety of industries for its chemical and physical properties. To optimise its performance, calcium carbonate must be ground to specific particle sizes, which directly influences its applications.

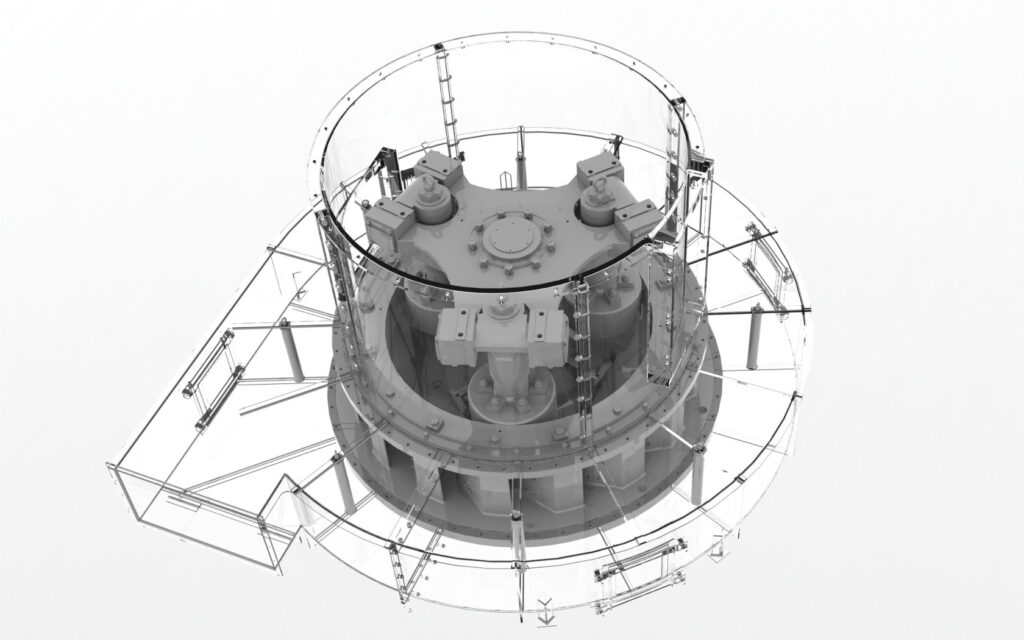

Operation of pendulum mill

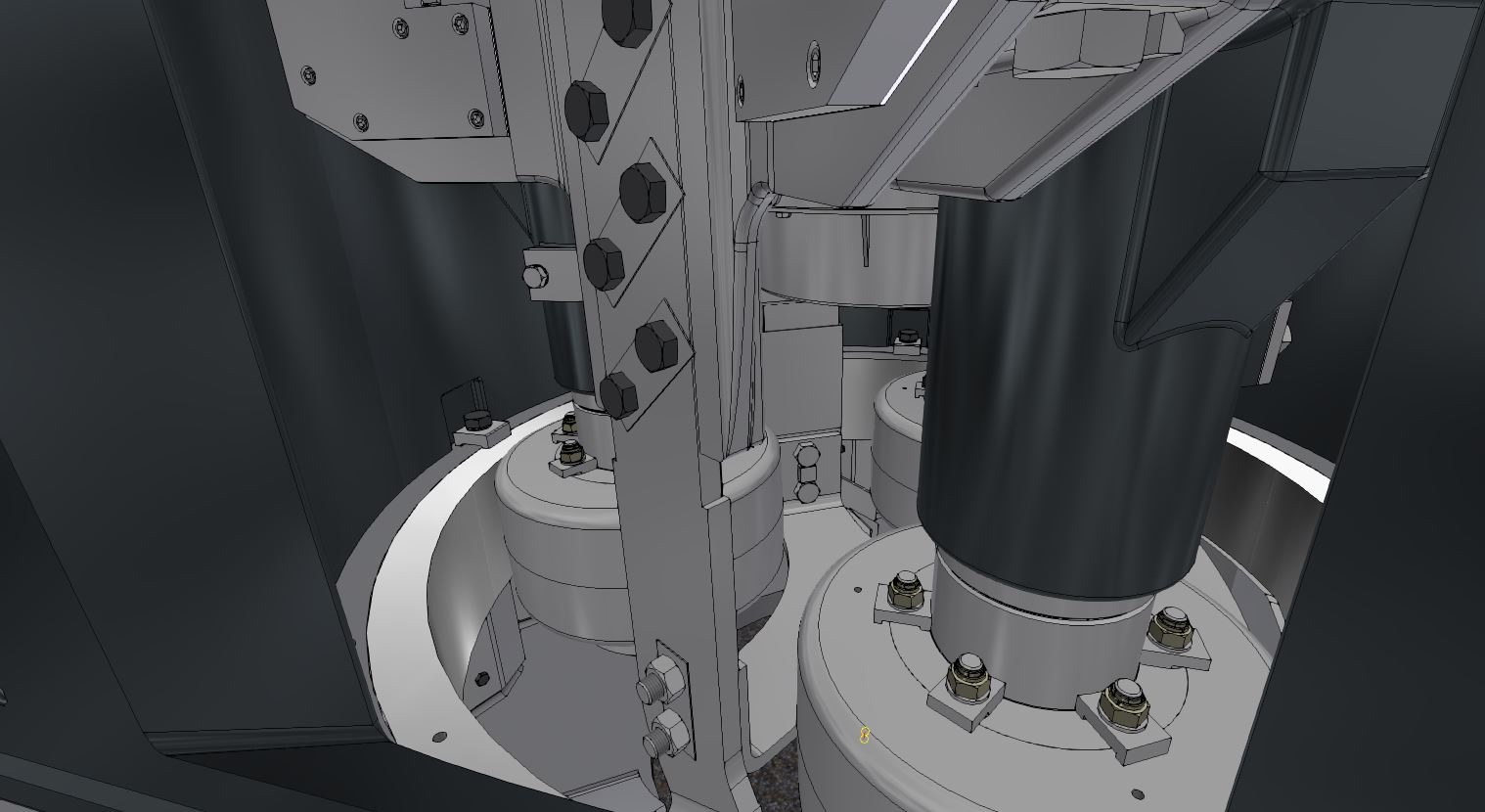

The pendulum mill reduces particle size by compression and shearing, using rollers that exert high pressure on the material against a grinding ring. This process ensures a precise and homogenous particle size, which is crucial for the specific applications of calcium carbonate.

Advantages of grinding with a pendulum mill

- Granulometric flexibility: Capable of producing a wide range of finenesses, meeting the requirements of different industrial applications.

- Energy efficiency and lower costs: The pendulum mill consumes less energy than other grinding methods, reducing production costs and improving competitiveness.

- Precise quality control: Integrated air classification systems effectively separate fine from coarse particles, ensuring a uniform particle size distribution and limiting over-shredding.

- Low component wear: Robust design using abrasion-resistant materials, minimising maintenance costs and extending equipment life.

- Absence of contamination: The dry grinding process preserves the purity of the calcium carbonate by avoiding the introduction of contaminants linked to moisture or foreign materials.

Save up to 40% energy with our technology.

Dry grinding of calcium carbonate using pendulum mills is an essential technique for obtaining high-quality powders tailored to the specific requirements of modern industries. Thanks to its advantages in terms of flexibility, particle size control and energy efficiency, the pendulum mill is the solution of choice for the production of calcium carbonate, meeting the market’s growing demand for ultra-fine and functional powders.

POITTEMILL offers equipment and process solutions adapted to the production of high-quality calcium carbonate, meeting the standards of industrial sectors.

Benefit from the advice of the POITTEMILL Group, experts in powder processing, drying and classification technology.

Our laboratory and testing centre offers numerous opportunities to test machines, parameters and processes, at both pilot and full scale, to ensure that the quality of your products and the efficiency of your operations generate maximum return on investment for your business.

CONTACT US

A project ? An information ?

At the cutting edge of innovation, the POITTEMILL Group has been designing its own equipment for over 90 years, offering customised turnkey solutions.